Wall forms an integral part of concrete building. The design are influenced by structural load bearing capability or non-load bearing element and location of walls in building plan.

| Characteristic | Precast concrete wall for residential building usually not flat panel but it has additional adjoining members like aircon ledge, window units with lintels, planter box etc. The uniformity in height and length are usually observed to assist repetitive casting with reduced number of mould variations. Precast wall for industrial building are usually flat but increased in height customised to match the storey height. |

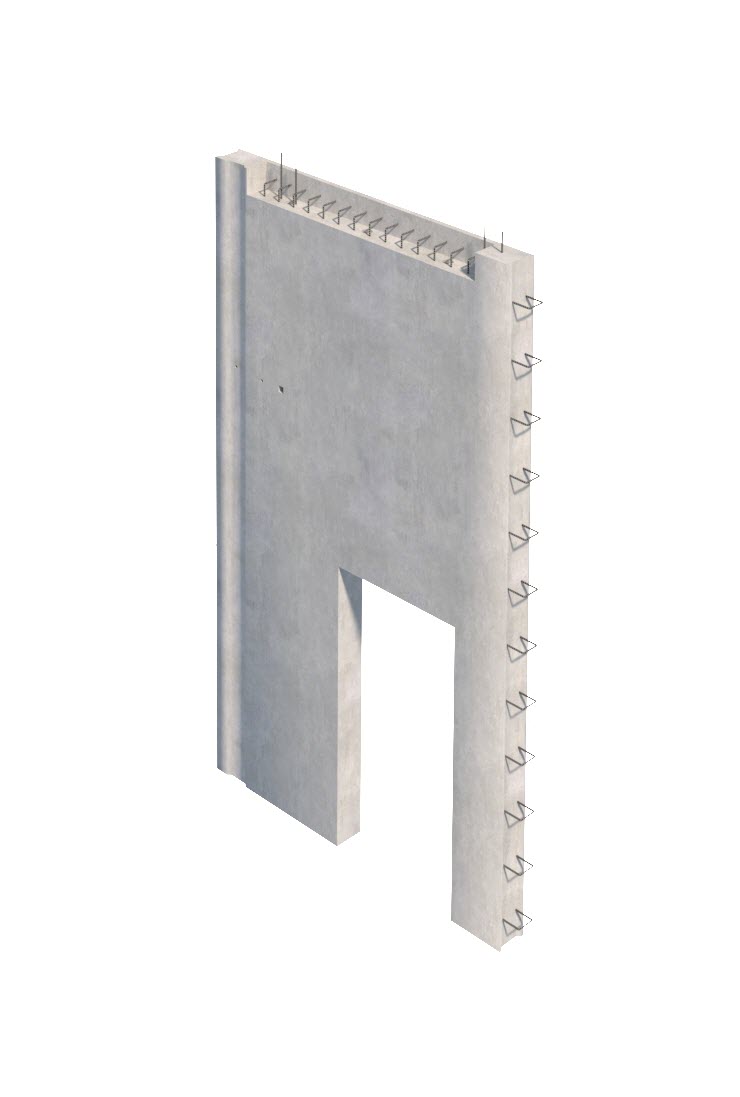

| Wall thickness | The load bearing structural walls ranges from 150 to 200mm thickness. The non load bearing walls are usually 100mm to 125mm thickness. |

| Panel size | For residential buildings, the common size 3m in height by 3m in length. The maximum dimension is about 3.6m Height by 12m length. |

| Window and Door | The windows and door metal frame are usually cast in during precast manufacturing. |

| Precast joints | The vertical joint are referred as joint necessary for the walls to be stackable from one storey to another. The horizontal joint are referred as joints necessary within a storey level usually between walls and adjoining structures. The shape of edges where joint features are provided varies from flat to rebate, shear key, recess, block outs or just roughened surface. The horizontal connections are usually with steel loop bar, wire loop system, starter bars, bolted connection etc. For vertical connections, it is also common to have splice sleeve, corrugated pipe – starter bar system or as simple as dowel bar connection. |