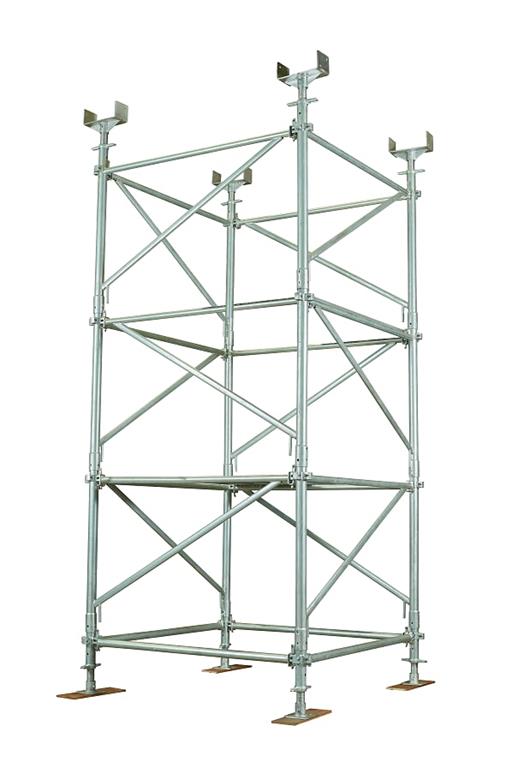

K.U.S HERC-60 shoring system is a temporary structure to carry the load of freshly poured concrete until it can support itself. It is a multidirectional shoring system for the concrete structure based on modular principle. The modular design of the triangle frame allows the construction of square or rectangular shaped shoring tower. The one-meter high triangle frames are manufactured with high quality welded and galvanized steel tubes according to the industry standard.

Herc-60 – Heavy Duty Shoring System

K.U.S HERC-60 shoring system is a temporary structure to carry the load of freshly poured concrete until it can support itself. It is a multidirectional shoring system for the concrete structure based on modular principle. The modular design of the triangle frame allows the construction of square or rectangular shaped shoring tower. The one-meter high triangle frames are manufactured with high quality welded and galvanized steel tubes according to the industry standard.

APPLICATION AREA

This system can be used to carry the load of system itself, workers, equipment for construction , maintenance, alteration or any demolition of the structure.

LOCKING MECHANISM

The Triangle Frames are designed with Connecting points (crab) in the vertical tubes, in addition to a self-locking wedge in the integrated ledger and diagonal bracing. Once a ledger of the Triangle frame is in contact with a crab, the wedge automatically pivots for instant assembly. A single hammer blow to the wedge is enough to strengthen the node connection. While dismantling, a reverse hammer blow is enough to unlock the wedge from the crab. With the same locking principle, Ledgers of different sizes could be used to connect two individual shoring towers.

K.U.S HERC-60 is erected with a few standard components no matter how high it is the tower. The Standard components are:

- The Basic Standard

- Triangle Frame

- Ledger

- Adjustable Jack Base

- Adjustable U-Head

EFFICIENT

Only 4 frames are required for building one level, in addition, the system’s the biggest component weighs less than 15kg which makes installation faster. As such, the number of workers needed to erect the system is significantly lower.

INTEGRATED SAFETY

The Triangle Frame is integrated with ledger and bracing which enhance the safety during the erection process. The self locking mechanism at the crab of frames creates a high tensile connection which allows the crane lifting of the system.

HIGH LOADING CAPACITY

Each post of the HERC-60 Triangle Frames can carry a safe working load of 6 tonnes. FLEXIBILITY K.U.S HERC-60 are compatible with adjustable telescopic components such as Jack base and U-Head used at the bottom and top of the tower to adjust the height. The shoring tower can be extended horizontally according to the site requirement with additional Standards and Ledgers.

HERC-60 Triangle Frame | Basic Standard | Standard | Ledger | Plan Brace | Adjustable Jack Base | Adjustable U-Head | Aluminium Beam – KUSAL

HERC-60 Triangle Frame

Triangle Frames are the main component which form the square or rectangular shoring tower. The vertical tubes have 3 stirrups and a ledger with the self locking wedge along with the integrated diagonal bracing.

| Item Description | Size |

|---|---|

| HERC-60

Triangle Frame |

700mm x 1000mm |

| 1500mm x 1000mm |

Basic Standard

Basic Standard is designed for setting out the shoring by placing it on the Adjustable Jack Base to create the base node. And it is also used to connect with Triangle Frame or Standard.

| Item Description | Size |

|---|---|

| Basic Standard | 300mm |

Standard

Standards are used with combination of triangle frames to produce narrower tower. The standards are used to adjust the height in the various site conditions. Additional standards are used in load concentrated areas.

| Item Description | Size |

|---|---|

| Standard | 300mm |

| 500mm | |

| 750mm | |

| 1000mm |

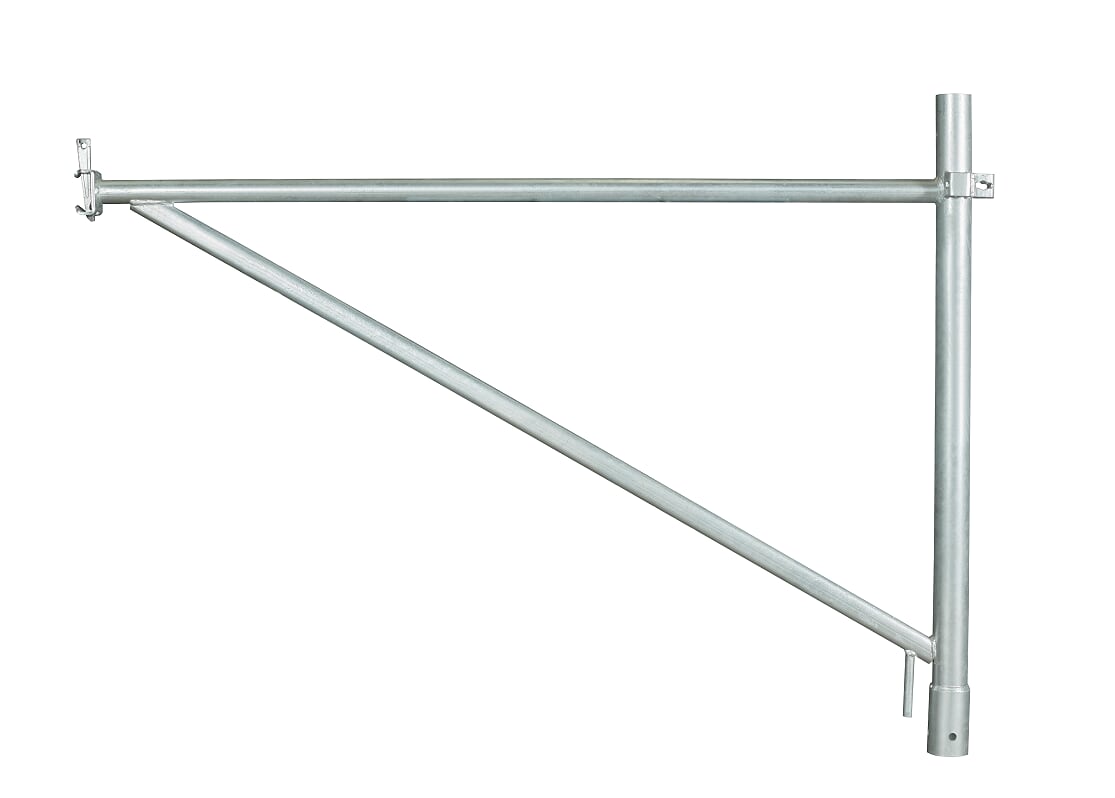

Ledger

Ledgers are the horizontal members with the wedges at both ends of the pipe in K.U.S HERC-60 system, which are used to connect individual shoring towers.

| Item Description | Size |

|---|---|

| Ledgers | 350mm |

| 500mm | |

| 750mm | |

| 1000mm | |

| 1500mm |

Plan Brace

Plan Brace ensures the formation of the tower squareness on the horizontal plane.

| Item Description | Size |

|---|---|

| Plan Brace | 700mm x 700mm |

| 700mm x 1500mm | |

| 1500mm x 1500mm |

Adjustable Jack Base

Adjustable Jack base is used as a starting base for the shoring. It has an Adjustable Jack Base height to accommodate uneven ground, setting the base of the shoring on the same level.

| Item Description | Size |

|---|---|

| Adjustable Jack Base | 48.3mm x 600mm |

Adjustable U-Head

Adjustable U-Head has an adjustable height to maintain uniform levels in formwork and to support joists or beams for shoring the horizontal members.

| Item Description | Size |

|---|---|

| Adjustable U-Head | 48.3mm x 600mm |

Aluminium Beam – KUSAL

K.U.S has developed various lengths of Aluminium beam such as KUSAL, which can be used as Aluminium stringer and joist in the shoring system.

| Item Description | Size |

|---|---|

| Aluminium

Beam-KUSAL |

Base width – 96

Height – 140mm Length – 1500mm, 2000mm, 3000mm, 4000mm, 6000mm and customizable length |

Assembling Instructions for Shoring System

Step 1 : Place the Adjustable Base jack on the sole plates. The spacing between the Adjustable Jack Bases is determined by the size of the shoring tower

Step 2 : Fix the Basic Standard into the Adjustable Jack Base. Connect the Ledgers with their integrated wedges into the Basic Standard. Adjust the base jacks if necessary and tighten the wedges into the crabs on Basic Standards and check the levels of the base

Step 3 : Insert the HERC-60 Triangle Frames into the Basic Standard and position it parallel to the base lift ledger. Attach the horizontal brace between two HERC-60 frames by knocking the pin into the crab to ensure the entire frame construction is in square or rectangular shape.

Step 4 : The shoring tower shall be extended in longitudinal and transverse directions by using HERC-60 Triangular Frames and Ledgers. The Triangle frames and ledgers shall be installed as per the previous steps.

Step 5 : Standing on the ground level, fix the HERC-60 frames for the second level of the shoring tower. The afore mentioned locking principle shall be used to connect the frames.

Step 6 : The shoring tower shall be extended vertically according to height requirement at site. The Standards and Ledgers shall be used to manage the final lift height or the HERC-60 frames shall be installed at the final lift. The working platforms shall be installed before moving on to the next level.

Step 7 : While on the working platform at second last lift, plug in the Adjustable U-Head. The formwork stringer, joist (Aluminum Beam, Wooden H-Beam) shall be installed along with plywood or any other formwork panel.

Dismantling Instructions for Shoring System

Step 1 : While standing on the working platform, the last lift components (i.e. HERC-60 frames, Standards, Ledgers, U-Head) shall be dismantled by loosening the wedge with a simple hammer blow. The components shall be passed to lower level.

Step 2 : While standing on the working platform of the second lift, components shall be dismantled as per HERC-60 locking mechanism. The working platform shall be dismantled where as necessary.

Step 3 : While standing on the ground, the first lift components shall be dismantled as per HERC-60 locking mechanism as well. The base elements such as Basic Standard, Adjustable Jack Base and sole plate shall be dismantled.