PLYWOOD has proved its worth in formwork construction in the past three decades, against increasing requirements for load carrying capacity and surface quality. K.U.S film-faced plywood is suitable for all types of formwork, whether it is a formwork system or loose panel formwork, slab or wall casting. It is suitable for flat or curved surfaces and the film protects the wood surface where it is exposed to the weather and concrete. The rigid film-faced surface not only prevents moisture absorption but also ensures excellent abrasion resistance in aggressive conditions and smooth finish to concrete formwork. Factory edges are painted to provide water and alkali resistance. Plywood sheets are 1220 x 2440 mm and come in 12 and 18 mm thickness.

Plywood

| MODEL | Supreme | Premium | Superplus |

|---|---|---|---|

| Wood Core | Hardwood (Origin: Asian) | ||

| Film | Brown film with Amphiply Supreme logo coated on both sides |

Brown film with Amphiply Premium logo coated on both sides |

Brown film with Amphiply Superplus logo coated on both sides |

| Glue | WBP Phenolic according to EN 314-3s | WBP Phenolic | WBP Phenolic |

| Sealed Edges | Yellow | Brown | Green |

| Usages | >15 uses* | 11 to 14 uses* | 8 to 10 uses* |

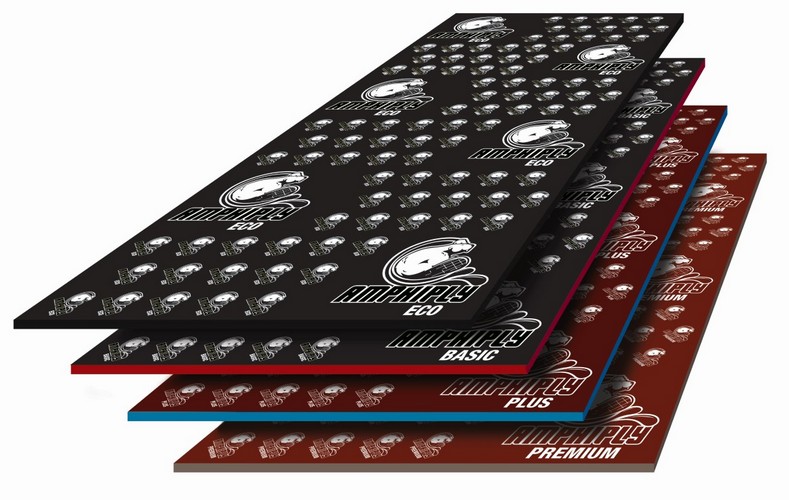

| MODEL | Plus | Basic | Original | Eco |

|---|---|---|---|---|

| Wood Core | Hardwood (Origin: Asian) | |||

| Film | Brown film with Amphiply Plus logo coated on both sides |

Black film with Amphiply Basic logo coated on both sides |

Black film with Amphiply Original logo coated on both sides |

Black film with Amphiply Black logo coated on both sides |

| Glue | WBP Melamine | WBP Melamine | WBP Melamine | WBP Melamine |

| Sealed Edges | Blue | Red | Black | Black |

| Usages | 5 to 7 uses* | 3 to 5 uses* | 2 to 3 uses* | 1 to 2 uses* |

* The approximate number of re-uses are only non-binding guide values. The actual number of re-uses may vary depending on the installation method, area of application, weather conditions and handling by workers.

* For further information and product inquiries, please contact us!